Product: Ultrasonic Fuel Level Monitoring in GPS Tracking

Ultrasonic Fuel Level Monitoring in GPS Tracking

Ultrasonic fuel level sensor is the fuel quantity monitoring equipment designed for fuel management. It can

prevent gasoline theft by drivers, optimize transportation cost, the driver’s driving action and assist

statistical decision, etc. The sensor uses ultrasonic probe to detect the oil level height and carries out smart

processing for height signal of oil quantity through built-in program of the main body. Then it sends the oil

quantity information to the system platform through GPS to generate the oil quantity report after analysis. The

sensor supports serial port and analog output and can connect with GPS of most brands/Beidou all-in-one machine.

Therefore, the sensor can be connected with the backstage monitoring system easily.

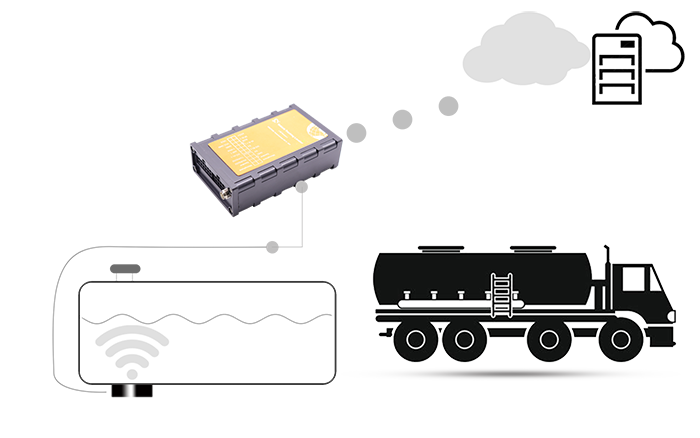

How does ultrasonic fuel level sensor Function in GPS tracking solution?

After ultrasonic fuel sensor installed under fuel tanks of vehicles, it would keep sending ultrasonic waves

out to detect the fuel depth in fuel tank. And transmit the data to gps tracking device.

What Features does the ultrasonic fuel sensor have?

● Higher precision for fuel level

The resolution ratio of oil level height measurement of the oil level sensor is 0.1mm and the measurement

accuracy is ±0.5%. High measurement accuracy can be guaranteed at high temperature and high cold external

environment.

● Long term stability

The oil level sensor adopts ultrasonic wave measurement method and performs non contact measurement. It is

different from the float-type, pressure type, magnetic sliding system measurement methods that adopt direct

contact measurement methods at present generally so as to avoid corrosion and pollution of oil level sensor by

fuel oil and maintain long-term stability.

● Easy installation and maintenance

It only needs to install the sensor probe at the lower part of external fuel tank. There is no need to change

the existing measurement system of the fuel tank, no need to drill hole and make change on the fuel tank. At

the same time, it can guarantee normal operation of former oil meter of vehicles.

● Avoid the dangers of boring holes or modifying fuel tanks

Non contact measurement makes it unnecessary to bore hole on or modify the fuel tank. No dirt and pollution

will be brought to the fuel oil.

● Strong reliability

Still work normally at hostile environment; anti-damp, anti-acid, inflaming retarding, anti-interference.

Can This Ultrasonic Fuel Sensor Work Independantly Of GPS Tracking Device?

Yes. Ultrasonic fuel snesor can be integrated into gps tracking device through analog input or RS232 / RS485

port. Users can use this sensor only with the LED display. the LED display would show measured liquid level.

Applicable scopes

The ultrasonic oil level sensor is geared to all types of vehicles (such as logistics vehicles, taxi, buses and

passenger cars, etc) to record the refueling, oil consumption of vehicles with digitalization to prevent

occurrence of fuel theft, avoid resources waste, improve management efficiency and traffic safety and enhance

operation management level.

Technical Properties

Operating Voltage

9-36V DC

Max power consumption

0.8W/12VDC

Working temperature

-40°C -- +85°C

Pressure bearing scope

≤0.8kg or 0.8MPa

Liquid measurement accuracy

±1%

Equipment interface

Provide output port of analog voltage/current, RS232 and RS485 data port.

Communication port parameters

The default baud rate is 9600. No check bit, 8-digit data bits, 1-digit stop bit and

no fluid control. The liquid level value measured by the sensor in a real-time manner is given per 10s after

smoothing processing.

Note: The baud rate and interval of data transmission can be customized.